PVDF resin for Solar backplane film

PVDF resin for Solar backplane film (DR206)

Product introduction

PVDF DR206 is the homopolymer of vinylidene fluoride , which has low melting viscosity. DS206 is one kind of thermoplastic fluororesin.It has fine mechanical strength and toughness, fine chemistry corrosion resistance and it is suitable to produce PVDF products by injection, extrusion and other processing technology.

Technical index

|

Item |

Unit |

DR206 |

Test Method/Standards |

|||

|

|

|

DR2061 |

DR2062 |

DR2063 |

DR2064 |

|

|

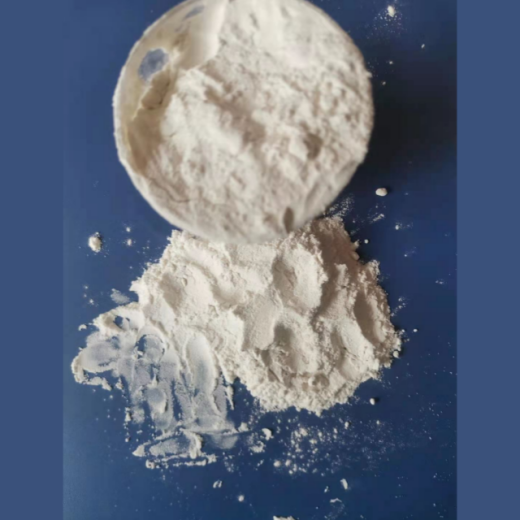

Appearance |

/ |

Pellet / Powder |

/ |

|||

|

Melting Index |

g/10min |

1.0 - 7.0 |

7.1-14.0 |

14.1-25.0 |

≥25.1 |

GB/T 3682 |

|

Tensile Strength,≥ |

Mpa |

35.0 |

GB/T 1040 |

|||

|

Elongation at break,≥ |

% |

25.0 |

GB/T 1040 |

|||

|

Standard relative density |

/ |

1.75 - 1.79 |

GB/T 1033 |

|||

|

Melting point |

℃ |

156 - 175 |

GB/T 28724 |

|||

|

Thermal decomposition,≥ |

℃ |

380 |

GB/T 33047 |

|||

|

Hardness |

Shore D |

70 - 80 |

GB/T 2411 |

|||

Application

DR206 is suitable for producing PVDF products by injection, extrusion and other processing technology.

Attention

Keep this product from high temperature to prevent toxic gas releasing at the temperature above 350°C.

Package, transportation and storage

1. Pellet packed in woven plastic bag with inner PE bag of 25kgs net each. Packed in antistatic bag ,lMT/bag.

Power packed in plastic drums, and circular barrels cutside, 40kg/drum, Packed in antistatic bag .500kg bag.

2. The product should be transported as non-dangerous product, avoiding heat, moisture and strong shock.

3. Stored in clearn and dry places, with in 5-30°C temperature range. Avoid contamination from dust and moisture..

|

|

|

||

|

|

|

keywords: PVDF resin for Solar backplane film

classification: Product

PVDF resin for Solar backplane film (DR206)

Product introduction

PVDF DR206 is the homopolymer of vinylidene fluoride , which has low melting viscosity. DS206 is one kind of thermoplastic fluororesin.It has fine mechanical strength and toughness, fine chemistry corrosion resistance and it is suitable to produce PVDF products by injection, extrusion and other processing technology.

Technical index

|

Item |

Unit |

DR206 |

Test Method/Standards |

|||

|

|

|

DR2061 |

DR2062 |

DR2063 |

DR2064 |

|

|

Appearance |

/ |

Pellet / Powder |

/ |

|||

|

Melting Index |

g/10min |

1.0 - 7.0 |

7.1-14.0 |

14.1-25.0 |

≥25.1 |

GB/T 3682 |

|

Tensile Strength,≥ |

Mpa |

35.0 |

GB/T 1040 |

|||

|

Elongation at break,≥ |

% |

25.0 |

GB/T 1040 |

|||

|

Standard relative density |

/ |

1.75 - 1.79 |

GB/T 1033 |

|||

|

Melting point |

℃ |

156 - 175 |

GB/T 28724 |

|||

|

Thermal decomposition,≥ |

℃ |

380 |

GB/T 33047 |

|||

|

Hardness |

Shore D |

70 - 80 |

GB/T 2411 |

|||

Application

DR206 is suitable for producing PVDF products by injection, extrusion and other processing technology.

Attention

Keep this product from high temperature to prevent toxic gas releasing at the temperature above 350°C.

Package, transportation and storage

1. Pellet packed in woven plastic bag with inner PE bag of 25kgs net each. Packed in antistatic bag ,lMT/bag.

Power packed in plastic drums, and circular barrels cutside, 40kg/drum, Packed in antistatic bag .500kg bag.

2. The product should be transported as non-dangerous product, avoiding heat, moisture and strong shock.

3. Stored in clearn and dry places, with in 5-30°C temperature range. Avoid contamination from dust and moisture..

|

|

|

||

|

|

|

last page

DOWREN NEW MATERIAL (HENAN) CO.,LTD

TELL:Selina.Liu +86-0393-8993626 / +86 18137458807

ADD:150 meters north of the intersection of Zhongyuan Road and Pushang Road, Puyang City,Henan Province

EMAIL:dowren@dowren.com

WhatsApp (+86 18137458807)