PTFE Molding powder Medum particle

PTFE

Product Description

Polytetrafluoroethylene (PTFE), also known as Teflon, commonly known as "plastic king", is a polymer made by polymerization of tetrafluoroethylene as a monomer, with a chemical formula of (C2F4)n, excellent heat resistance and cold resistance, and can be used for a long time at -180~260ºC. This material is resistant to acids and alkalis, various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, and its coefficient of friction is very low, so it can be used for lubrication, and it has also become an ideal coating for the inner layer of water pipes that are easy to clean.

Grades and Technical Properties

PTFE Medium Size Particle Resin:

|

Property |

Normal Value |

||

|

DR-9Z |

DR-12Z |

DR-18Z |

|

|

Appearance |

White powder,no impurities |

||

|

Tensile Strength,MPa≥ |

25.5 |

||

|

Elongation at Break,%≥ |

250 |

||

|

Water content %≤ |

0.040 |

||

|

Bulk Density,g/L |

400-750 |

||

|

Average particle Size,μm |

60-100 |

101-160 |

100-260 |

|

Standard Specific Gravity |

2.130-2.180 |

||

|

Melting peak temperature℃ |

322-332 |

||

|

Thermal instability index≤ |

50 |

||

Application

1、Anti-corrosion: PTFE material has been widely used in many industries such as petroleum and textile due to its outstanding corrosion resistance. Among them, the representative ones include exhaust pipes, steam pipes, high, medium and low pressure pipelines, valves, etc. Especially under harsh environmental conditions such as low temperature and anti-sticking, which cannot be used with conventional materials, PTFE has more advantages.

2、Electrical and electronics: PTFE has a relatively small dielectric constant, so it can be used in the preparation of enameled wires for use in micro motors. In addition, fluoroplastic films have a certain selective permeability to various gases, so oxygen sensors can be fabricated using this feature. Today, many forms of PTFE materials play an important role in the field of electrical and electronic insulation. PTFE glass paint cloth and glass cloth are used to make high-temperature and high-frequency insulating materials, which can be used in satellite communication and computers. PTFE film is used to make capacitors, as an insulating layer, gasket, cable, etc. between instruments; PTFE thin-walled pipes of different calibers are used for lead-out bushings, heat shrinkable pipes and spiral pipes, and insulated water diversion pipes for generators.

3、In recent years: PTFE membranes have been developed at home and abroad as artificial organs, such as artificial blood vessels, heart valves, etc., for example, it has been used as a prosthetic stent material in artificial blood vessels and rhinoplasty in clinical practice, and has achieved good results.

4、In terms of construction: by coating PTFE resin on ultra-fine glass fiber fabric, PTFE membrane has the characteristics of light weight, high strength, fireproof and flame retardant, good self-cleaning, not affected by ultraviolet rays, fatigue resistance, twist resistance, aging resistance, long service life, high light transmittance, and low heat absorption. It is precisely because of the invention of this cross-era membrane material that the membrane structure building has become a modern permanent building.

5、Low friction performance in terms of load: Because its coefficient of friction is relatively low compared to most solid materials, filled PTFE has gradually evolved into an excellent material for oil-free lubrication of various parts. It is used in a wide range of applications, including bearings for chemical equipment, piston rings, supporting sliders for steel structure roof trusses, and bridging turns.

|

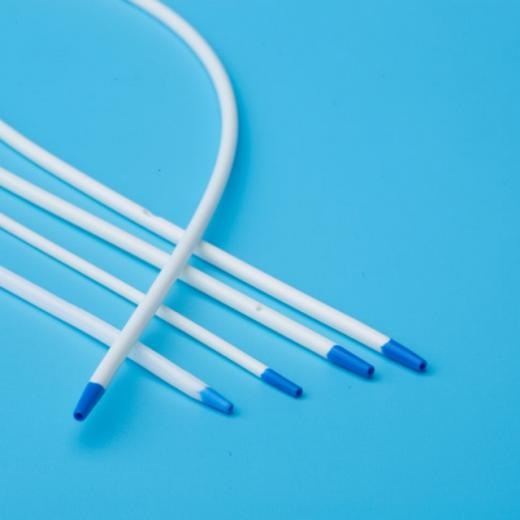

PTFE Medical Catheters |

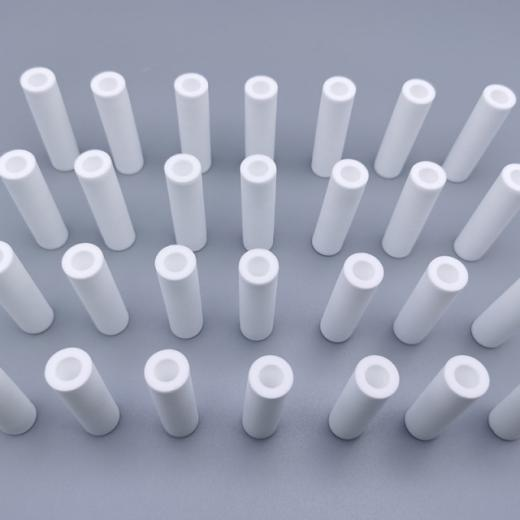

PTFE sintered filters |

PTFE seals |

|

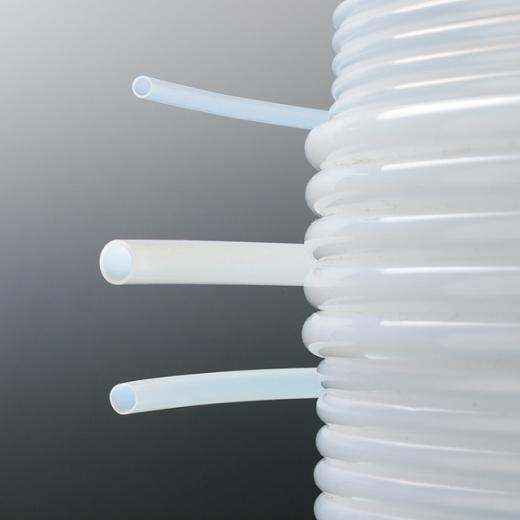

PTFE filter tubing |

PTFE valves |

PTFE sheet |

|

PTFE hose |

PTFE membranes |

keywords: PTFE Molding powder Medum particle

classification: Product

PTFE

Product Description

Polytetrafluoroethylene (PTFE), also known as Teflon, commonly known as "plastic king", is a polymer made by polymerization of tetrafluoroethylene as a monomer, with a chemical formula of (C2F4)n, excellent heat resistance and cold resistance, and can be used for a long time at -180~260ºC. This material is resistant to acids and alkalis, various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance, and its coefficient of friction is very low, so it can be used for lubrication, and it has also become an ideal coating for the inner layer of water pipes that are easy to clean.

Grades and Technical Properties

PTFE Medium Size Particle Resin:

|

Property |

Normal Value |

||

|

DR-9Z |

DR-12Z |

DR-18Z |

|

|

Appearance |

White powder,no impurities |

||

|

Tensile Strength,MPa≥ |

25.5 |

||

|

Elongation at Break,%≥ |

250 |

||

|

Water content %≤ |

0.040 |

||

|

Bulk Density,g/L |

400-750 |

||

|

Average particle Size,μm |

60-100 |

101-160 |

100-260 |

|

Standard Specific Gravity |

2.130-2.180 |

||

|

Melting peak temperature℃ |

322-332 |

||

|

Thermal instability index≤ |

50 |

||

Application

1、Anti-corrosion: PTFE material has been widely used in many industries such as petroleum and textile due to its outstanding corrosion resistance. Among them, the representative ones include exhaust pipes, steam pipes, high, medium and low pressure pipelines, valves, etc. Especially under harsh environmental conditions such as low temperature and anti-sticking, which cannot be used with conventional materials, PTFE has more advantages.

2、Electrical and electronics: PTFE has a relatively small dielectric constant, so it can be used in the preparation of enameled wires for use in micro motors. In addition, fluoroplastic films have a certain selective permeability to various gases, so oxygen sensors can be fabricated using this feature. Today, many forms of PTFE materials play an important role in the field of electrical and electronic insulation. PTFE glass paint cloth and glass cloth are used to make high-temperature and high-frequency insulating materials, which can be used in satellite communication and computers. PTFE film is used to make capacitors, as an insulating layer, gasket, cable, etc. between instruments; PTFE thin-walled pipes of different calibers are used for lead-out bushings, heat shrinkable pipes and spiral pipes, and insulated water diversion pipes for generators.

3、In recent years: PTFE membranes have been developed at home and abroad as artificial organs, such as artificial blood vessels, heart valves, etc., for example, it has been used as a prosthetic stent material in artificial blood vessels and rhinoplasty in clinical practice, and has achieved good results.

4、In terms of construction: by coating PTFE resin on ultra-fine glass fiber fabric, PTFE membrane has the characteristics of light weight, high strength, fireproof and flame retardant, good self-cleaning, not affected by ultraviolet rays, fatigue resistance, twist resistance, aging resistance, long service life, high light transmittance, and low heat absorption. It is precisely because of the invention of this cross-era membrane material that the membrane structure building has become a modern permanent building.

5、Low friction performance in terms of load: Because its coefficient of friction is relatively low compared to most solid materials, filled PTFE has gradually evolved into an excellent material for oil-free lubrication of various parts. It is used in a wide range of applications, including bearings for chemical equipment, piston rings, supporting sliders for steel structure roof trusses, and bridging turns.

|

PTFE Medical Catheters |

PTFE sintered filters |

PTFE seals |

|

PTFE filter tubing |

PTFE valves |

PTFE sheet |

|

PTFE hose |

PTFE membranes |

last page

Next

DOWREN NEW MATERIAL (HENAN) CO.,LTD

TELL:Selina.Liu +86-0393-8993626 / +86 18137458807

ADD:150 meters north of the intersection of Zhongyuan Road and Pushang Road, Puyang City,Henan Province

EMAIL:dowren@dowren.com

WhatsApp (+86 18137458807)